FREEHAND BLACKSMITHING

Traditional craftsmanship throughout Austria, inscribed 2022

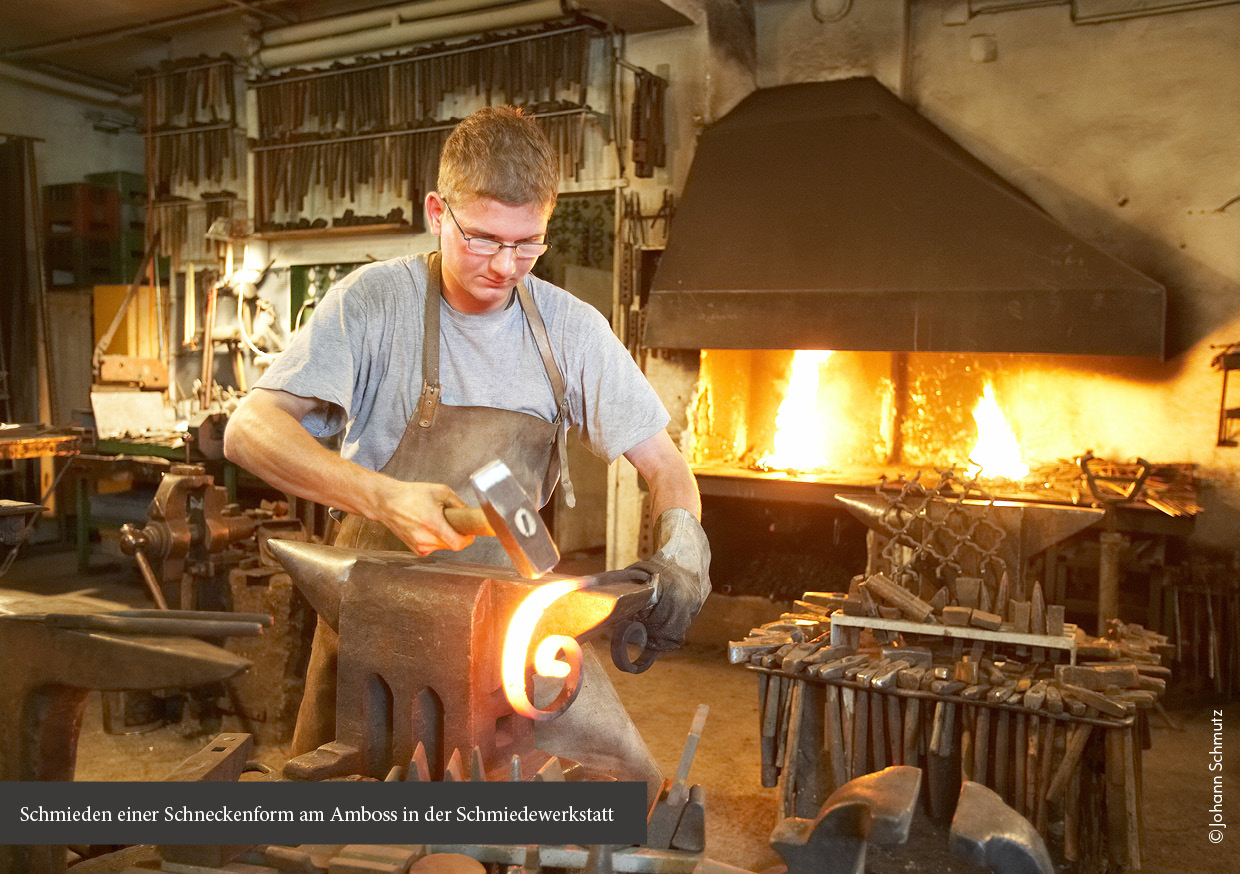

Fire, air, water, and earth—freehand blacksmithing involves working with all four elements. Today, as in the past, the process of working wrought iron and steel involves beating or pressing it by hand while it is hot. The materials are shaped using centuries-old techniques involving different forging processes and using sticks and hammers. The resulting forged (art) objects range from stately insignia to building elements.

The craft of blacksmithing emerged in parallel with the art of metal extraction. Initial origins of the blacksmith's craft could be found in ancient Egypt (ca. 1500 BC); in Europe, there is concrete evidence in the Hallstatt Period around 1000 BC. Since then, blacksmithing has been an important part of societal culture, be it through its contribution to architecture, or through the production of jewellery, sacred objects, or the ornate decoration of everyday objects. In many cases, machines have now replaced this work. Nevertheless, just under a hundred Austrian companies practise the craft of freehand blacksmithing today. In the freehand technique, the blacksmith first makes a sketch of the piece, detailing the applicable proportions. The appropriate material is then selected, prepared, and cut to size. The forge fire is then lit, and the materials are shaped and joined together to form workpieces using different forging techniques as well as sticks and hammers. Classic workshops still bear great similarities to those that existed hundreds of years ago. Here, you will find a forge or a furnace with a fire bowl, where the wrought iron is made to glow, and tools such as hand hammers and set hammers, which are used as sledgehammers to shape the workpiece. A blacksmith’s knowledge encompasses both the production of objects as well as their repair and maintenance. As such, blacksmiths make a contribution against the throwaway society. Many of the knowledge bearers also frequently make the tools and templates they need themselves in their workshops.

The traditional techniques of working and hardening the workpieces require many years of experience. They are passed on to the apprentices in the apprenticeship trade, above all by experienced master craftsmen. Once they have successfully passed the master craftsman's examination, the young blacksmiths hammer a self-made nail, as a "business card”, into an old oak trunk that has already been filled with nails by many previous generations. In addition, the blacksmiths each have their own hallmark, which is then stamped into every workpiece. They always try to expand their own knowledge by means of regular exchange between experts from all federal provinces and from abroad. Finally, by opening the workshops to visitors, organising competitions, and cooperating with schools, measures are taken that contribute to the safeguarding of the element.

Downloads

- Expertise Breitwieser (in German only) 1 MB (pdf)

- Expertise Elgaß (in German only) 196 KB (pdf)

- Expertise Stockinger (in German only) 154 KB (pdf)

- Application form (in German only) 295 KB (pdf)

![[Translate to EN:] © J. Ségur/ZED, with the permission of UNESCO](/fileadmin/_processed_/d/b/csm_Convention-2003-IKE_0832a6a47d.jpg)

![[Translate to EN:] © ÖUK](/fileadmin/_processed_/3/9/csm_P1011318_7eac86402f.jpg)

![[Translate to EN:] © Weitblickfilm](/fileadmin/_processed_/9/8/csm_Workshop_17_2dee1e1fd8.jpg)